At Knitsourcing Inc, our robust infrastructure is the backbone of our manufacturing excellence. Located in Tirupur, our integrated facility is equipped with advanced knitting, dyeing, printing, and stitching units. We ensure streamlined production, high-quality output, and timely delivery to meet the dynamic needs of global clients.

Cotton Fields is our signature collection that celebrates the purity and comfort of 100% cotton. Crafted with care at Knitsourcing Inc’s state-of-the-art facilities in Tirupur, each piece blends softness, breathability, and timeless style. Designed for everyday wear, Cotton Fields reflects our commitment to quality, sustainability, and thoughtful craftsmanship.

At Knitsourcing Inc, we begin with the finest quality fibers to ensure excellence from the very first stage. Our spinning process delivers high-grade yarns with superior strength, consistency, and softness. With a focus on sustainability and innovation, we work with trusted mills to produce yarns that meet global standards for comfort and durability.

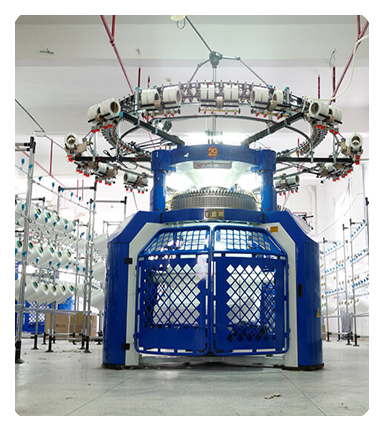

Our knitting division forms the core of our fabric production capabilities. At Knitsourcing Inc, we utilize advanced circular and flat knitting machines to produce a wide range of fabrics including single jersey, rib, interlock, pique, and more. Precision and consistency are key, ensuring high-quality fabrics tailored to meet the diverse needs of our global clientele.

At Knitsourcing Inc, our dyeing process combines precision, eco-conscious practices, and vibrant results. We partner with state-of-the-art dyeing units equipped with soft flow and air flow machines to ensure uniform color, fabric softness, and minimal environmental impact. Our commitment to quality and sustainability ensures every fabric meets international colorfastness and safety standards.

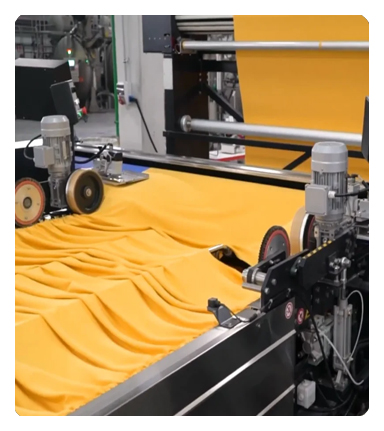

Our finishing process adds the final touch of quality to every fabric. At Knitsourcing Inc, we ensure superior hand feel, shrinkage control, and dimensional stability through advanced compacting, calendaring, and bio-wash treatments. Each fabric is finished to meet global standards, enhancing both appearance and performance for the end user.

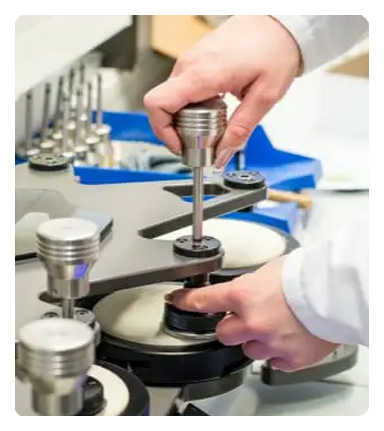

Quality is non-negotiable at Knitsourcing Inc. Our in-house test lab is equipped with modern testing equipment to ensure every fabric and garment meets international quality and compliance standards. From colorfastness, shrinkage, and pilling resistance to fabric strength and dimensional stability, we conduct rigorous tests at every stage to guarantee consistent excellence.

Our state-of-the-art production unit is the heart of Knitsourcing Inc’s manufacturing excellence. Located in Tirupur, it is equipped with modern stitching machines, skilled manpower, and streamlined workflows to ensure high-quality garment output. With dedicated lines for various product categories, we maintain flexibility, speed, and precision in handling bulk orders while meeting strict international standards.

The cutting section plays a vital role in garment manufacturing. Fabrics are precisely layered and cut using advanced machines to ensure accuracy, consistency, and minimal wastage. This step sets the foundation for perfect stitching and overall garment quality.

The sewing section is the core of garment assembly, where cut components are stitched together with precision. Equipped with modern sewing machines and skilled operators, Ensures strong seams, accurate construction, and high-quality finishes for every garment.

In the checking section, each garment undergoes thorough inspection to identify and correct any defects. Our quality team ensures that stitching, measurements, trims, and overall appearance meet the required standards before moving to the next stage of production.

Our quality control section ensures excellence at every stage of production. From fabric inspection to final garment checks, each step is monitored against strict quality standards to deliver defect-free, high-performance garments that meet global expectations.

The ironing section enhances the final look and feel of each garment. Using advanced steam press and flat-bed machines, garments are carefully pressed to remove wrinkles, improve appearance and quality , and ensure a clean, crisp finish before packing in each products.

Our garments packing section, each garment is neatly folded, tagged, and packed as per buyer specifications. We ensure secure, clean, and presentation-ready packaging that protects the product and enhances its appeal for retail or shipment on that time.

At Knitsourcing Inc, quality is at the core of everything we do. From sourcing premium raw materials to rigorous in-process inspections and final product checks, we adhere to stringent quality control protocols. Our dedicated quality assurance team ensures that every garment meets international standards for durability, fit, and finish, delivering consistent excellence to our global customers.

Knitsourcing Inc offers seamless logistics solutions to ensure timely delivery and smooth supply chain management. Strategically located in Tirupur, we coordinate with reliable transport partners and utilize efficient warehousing systems to handle bulk shipments worldwide. Our streamlined logistics process minimizes lead times and ensures your products reach their destination safely and on schedule.

Knitsourcing Inc is a leading garment manufacturer and buying services company based in Tirupur, India.– one of the world’s most recognized hubs for textile and apparel production.

Know where to find us? Let's take a look and get in touch !

Copyright © 2025 KNIT SOURCING INC. All rights reserved. Design by Skywalk Technologies.